- Description

- Specifications

- Documents

Two Channel Rework System with T245 and DR560 (Shop Air Not Required)

The JBC DDSE-1QE is a two-channel rework system. The DDSE-1QE includes the T245-A general purpose iron (tips sold separately), DR560-A desoldering iron (with C560003 nozzle, 1mm), as well as the MSE-B electric desoldering module.

Please note: This system has an electric pump; DDSE-1QE does NOT require an external source of compressed air.

Features and Benefits:

Two channel rework system

Soldering and vacuum functionality

Includes DDE two tool control unit

Includes T245 general purpose iron (tips sold separately)

Includes DR560 desoldering iron (includes C560003 nozzle)

Includes MSE-B electric desoldering module

Desoldering module does NOT require external source of compressed air

Compatible with a wide variety of tools and peripherals

DDSE Station Includes:

DDE Control Unit operates with 2 soldering or desoldering tools simultaneously and is fully compatible with 10 different JBC Tools delivering up to 150 W per tool.

MSE Electric Desoldering Module is ideal for a complete desoldering process. Delivering unmatched suction power and achieving an 85% vacuum.

T245 General Purpose Handle is perfect for both SMDs and jobs with high-power requirements (e.g. ground plane soldering).

DR560 Desoldering Iron is used for desoldering jobs of through-hole components and removing excess solder after SMD rework. Provides up to 160W.

C245 Cartridge Range is suitable for general soldering purposes and they are perfect for both SMD components or for applications with high power requirements

C560 Tip Range offer instant heat up, excellent heat transfer and great durability.

JBC's wide range of Tools feature soldering and rework irons that guarantee maximum efficiency. The short distance tip-to-grip allows you more control and the highest precision. JBC tools are currently the smallest the lightest and the most ergonomic.

Intelligent Heat System

Delivers the highest rework quality, powered by JBC's Most Efficient Soldering System and advanced Intelligent Heat Management, which optimizes heat control to extend tip life and minimize energy consumption.

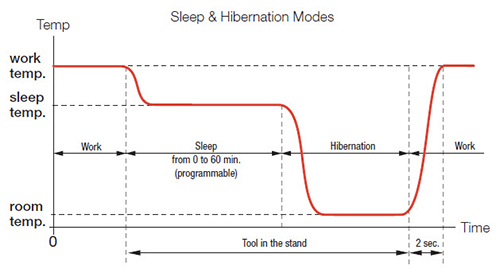

Sleep and Hibernation Modes

Sleep Mode automatically lowers the tip temperature below the solder melting point when the tool rests in the stand. It prevents the dissolution of the iron tip coating into molten solder.

After a configurable period of tool inactivity in the stand, the tool enters Hibernation Mode. It cuts off the power supply, making the tip reach room temperature, thus preventing oxidation and saving energy.

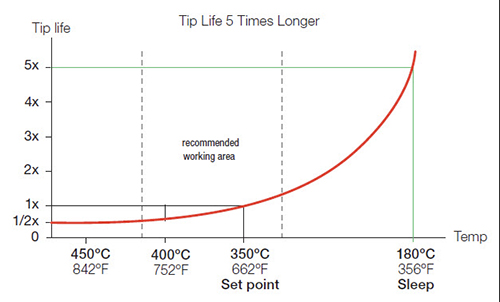

Longer Tip Life

Tip life increases exponentially by using lower temperatures as shown. Using Sleep Mode, the temperature is further reduced, which multiplies tip life by 5.

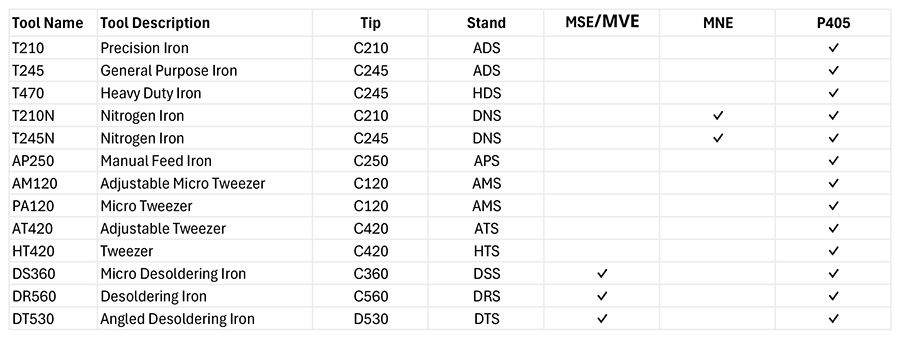

DDE Station Tool Compatibility

The DDE control station is compatible with several additional tools, covering a wide variety of soldering and rework applications.

The chart below provides an overview of each tool, along with a compatible stand and tip series.

JBC DDSE-1QE Product Details:

Nominal power: 370W

Peak power: 150 W per tool

Selectable temperature: 90 to 450 ºC / 190 to 840 ºF

Idle temp. stability (still air): ±1.5ºC / ±3ºF

Meets and exceeds IPC J-STD-001FVacuum: 85 % / 640 mmHg / 25.4 inHg

Flow rate: 35 SLPM

Temperature accuracy: ±3% (using reference cartridge)

Temp. adjustment: ±50ºC / ±90ºF Through station menu setting

Tip-to-ground resistance: <2 ohms

Tip-to-ground voltage: <2 mV RMS